Associate Professor Ronald Rael Speaks at AAAS Annual Meeting

Digital Fabrication in Architecture and 3D Printing Materials in Focus at AAAS Annual Meeting

While the use of 3D printing in the construction field is not a new concept, advancements in the field are rapidly changing the industry and the implications it could have on housing and development. Last month at the American Association for the Advancement of Science (AAAS) 2017 annual meeting in Boston, researchers revealed some of the latest developments in digital fabrication in architecture, including 3D printing. The process of digital fabrication joins production and design together, using 3D modeling or CAD software, and both additive and subtractive manufacturing processes.

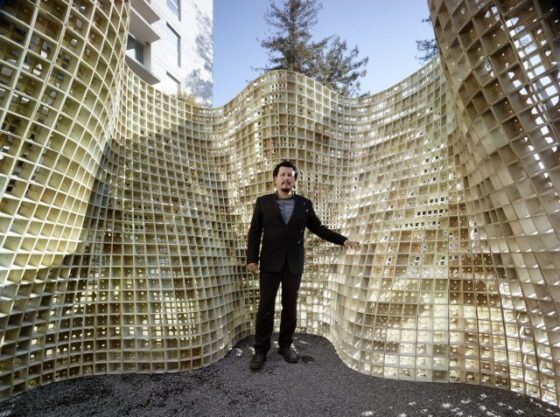

Associate Professor of Architecture and co-founder of EmergingObjects Ronald Rael was one of the speakers at the conference, and talked about how digital fabrication technologies can be integrated in planning, design, and building processes to disrupt the building industry. Professor Rael previously co-developed a patented fiber-reinforced cement polymer which was used in the exterior construction of the 3D Printed House 1.0 project back in 2014. The home’s interior was created using a salt polymer, which Emerging Objects calls Saltygoo. Rael’s EmergingObjects team also developed a formula that allowed them to use recycled rubber content in 3D printing using tires.

While most 3D printing materials were originally developed to be used for relatively small objects, not large-scale ones, interdisciplinary research is helping develop new architectural additive manufacturing methods, Rael explained. He also added that he is currently working to develop new materials to 3D print from, which would be cost effective and scalable on a 1:1 construction scale. “3D printing architecture solutions involve a material supply from sustainable resources, culled from waste streams or consideration of the efficiency of a building product’s digital materiality,” he explained.